In the rapidly evolving landscape of biomanufacturing, the imperative for innovation and operational efficiency has never been more pressing. A recent conversation with Michael Burton, a seasoned expert in the biopharma sector, reveals the critical challenges and emerging opportunities that biomanufacturers face today. With a wealth of experience encompassing operational roles in life sciences, software solutions, and health tech startups, Michael provides a nuanced perspective on the ongoing evolution of this vital industry.

In the rapidly evolving landscape of biomanufacturing, the imperative for innovation and operational efficiency has never been more pressing. A recent conversation with Michael Burton, a seasoned expert in the biopharma sector, reveals the critical challenges and emerging opportunities that biomanufacturers face today. With a wealth of experience encompassing operational roles in life sciences, software solutions, and health tech startups, Michael provides a nuanced perspective on the ongoing evolution of this vital industry.

In the rapidly evolving landscape of biomanufacturing, the imperative for innovation and operational efficiency has never been more pressing. A recent conversation with Michael Burton, a seasoned expert in the biopharma sector, reveals the critical challenges and emerging opportunities that biomanufacturers face today. With a wealth of experience encompassing operational roles in life sciences, software solutions, and health tech startups, Michael provides a nuanced perspective on the ongoing evolution of this vital industry.

In the rapidly evolving landscape of biomanufacturing, the imperative for innovation and operational efficiency has never been more pressing. A recent conversation with Michael Burton, a seasoned expert in the biopharma sector, reveals the critical challenges and emerging opportunities that biomanufacturers face today. With a wealth of experience encompassing operational roles in life sciences, software solutions, and health tech startups, Michael provides a nuanced perspective on the ongoing evolution of this vital industry.

If you're not playing with AI every single day on your own, you're missing out.

If you're not playing with AI every single day on your own, you're missing out.

If you're not playing with AI every single day on your own, you're missing out.

If you're not playing with AI every single day on your own, you're missing out.

The Transformation of Biomanufacturing

Reflecting on the significant shifts within the biopharma sector over the past few decades, Michael highlights a time when drug manufacturing primarily involved the production of straightforward compounds—essentially “stamping out pills.” The landscape has dramatically transformed with the emergence of complex disease states and biologics, necessitating the establishment of sophisticated manufacturing facilities that often require billions in investment, yet may yield only a liter of product per day.

This complexity introduces a host of challenges, particularly the integration of disparate data systems and the necessity to streamline processes to maintain competitive advantage. As Michael notes, “Manufacturing has sort of been left behind,” especially in comparison to the advancements achieved in clinical and regulatory domains. Consequently, many companies have turned to contract manufacturing solutions, which, while expedient, often come at the expense of control over critical manufacturing processes.

Reflecting on the significant shifts within the biopharma sector over the past few decades, Michael highlights a time when drug manufacturing primarily involved the production of straightforward compounds—essentially “stamping out pills.” The landscape has dramatically transformed with the emergence of complex disease states and biologics, necessitating the establishment of sophisticated manufacturing facilities that often require billions in investment, yet may yield only a liter of product per day.

This complexity introduces a host of challenges, particularly the integration of disparate data systems and the necessity to streamline processes to maintain competitive advantage. As Michael notes, “Manufacturing has sort of been left behind,” especially in comparison to the advancements achieved in clinical and regulatory domains. Consequently, many companies have turned to contract manufacturing solutions, which, while expedient, often come at the expense of control over critical manufacturing processes.

Reflecting on the significant shifts within the biopharma sector over the past few decades, Michael highlights a time when drug manufacturing primarily involved the production of straightforward compounds—essentially “stamping out pills.” The landscape has dramatically transformed with the emergence of complex disease states and biologics, necessitating the establishment of sophisticated manufacturing facilities that often require billions in investment, yet may yield only a liter of product per day.

This complexity introduces a host of challenges, particularly the integration of disparate data systems and the necessity to streamline processes to maintain competitive advantage. As Michael notes, “Manufacturing has sort of been left behind,” especially in comparison to the advancements achieved in clinical and regulatory domains. Consequently, many companies have turned to contract manufacturing solutions, which, while expedient, often come at the expense of control over critical manufacturing processes.

Reflecting on the significant shifts within the biopharma sector over the past few decades, Michael highlights a time when drug manufacturing primarily involved the production of straightforward compounds—essentially “stamping out pills.” The landscape has dramatically transformed with the emergence of complex disease states and biologics, necessitating the establishment of sophisticated manufacturing facilities that often require billions in investment, yet may yield only a liter of product per day.

This complexity introduces a host of challenges, particularly the integration of disparate data systems and the necessity to streamline processes to maintain competitive advantage. As Michael notes, “Manufacturing has sort of been left behind,” especially in comparison to the advancements achieved in clinical and regulatory domains. Consequently, many companies have turned to contract manufacturing solutions, which, while expedient, often come at the expense of control over critical manufacturing processes.

The Role of Technology in Biomanufacturing

As the biopharma industry grapples with these challenges, the incorporation of innovative technologies becomes paramount. The advent of artificial intelligence (AI) and advanced data analytics presents exciting opportunities for optimizing manufacturing processes. Michael emphasizes that these tools should be regarded not as threats, but as invaluable assets: “If you're not playing with AI every single day on your own, you're missing out.”

AI’s capability to analyze vast datasets and identify patterns offers manufacturers the potential for real-time decision-making, significantly enhancing efficiency and yield. In an industry where even marginal improvements can yield substantial financial benefits, the transition from outdated legacy systems to AI-driven solutions is not merely advantageous but essential for fostering innovation.

As the biopharma industry grapples with these challenges, the incorporation of innovative technologies becomes paramount. The advent of artificial intelligence (AI) and advanced data analytics presents exciting opportunities for optimizing manufacturing processes. Michael emphasizes that these tools should be regarded not as threats, but as invaluable assets: “If you're not playing with AI every single day on your own, you're missing out.”

AI’s capability to analyze vast datasets and identify patterns offers manufacturers the potential for real-time decision-making, significantly enhancing efficiency and yield. In an industry where even marginal improvements can yield substantial financial benefits, the transition from outdated legacy systems to AI-driven solutions is not merely advantageous but essential for fostering innovation.

As the biopharma industry grapples with these challenges, the incorporation of innovative technologies becomes paramount. The advent of artificial intelligence (AI) and advanced data analytics presents exciting opportunities for optimizing manufacturing processes. Michael emphasizes that these tools should be regarded not as threats, but as invaluable assets: “If you're not playing with AI every single day on your own, you're missing out.”

AI’s capability to analyze vast datasets and identify patterns offers manufacturers the potential for real-time decision-making, significantly enhancing efficiency and yield. In an industry where even marginal improvements can yield substantial financial benefits, the transition from outdated legacy systems to AI-driven solutions is not merely advantageous but essential for fostering innovation.

As the biopharma industry grapples with these challenges, the incorporation of innovative technologies becomes paramount. The advent of artificial intelligence (AI) and advanced data analytics presents exciting opportunities for optimizing manufacturing processes. Michael emphasizes that these tools should be regarded not as threats, but as invaluable assets: “If you're not playing with AI every single day on your own, you're missing out.”

AI’s capability to analyze vast datasets and identify patterns offers manufacturers the potential for real-time decision-making, significantly enhancing efficiency and yield. In an industry where even marginal improvements can yield substantial financial benefits, the transition from outdated legacy systems to AI-driven solutions is not merely advantageous but essential for fostering innovation.

Navigating the Future with Katalyze AI

The conversation naturally led to the pivotal role of Katalyze AI in this technological transformation. Positioned at the forefront of integrating advanced technology into biomanufacturing, Katalyze AI facilitates smoother data integration and real-time analytics. By harnessing the power of AI, manufacturers can not only enhance operational efficiencies but also adeptly navigate the complexities of contemporary drug development.

Michael asserts that the future of biomanufacturing is contingent upon the industry’s adaptability to these changes. As companies explore AI-driven solutions, they can unlock unprecedented levels of productivity and responsiveness. “In this very, very complex, competitive world, being able to produce even a little bit more from your manufacturing is going to unlock a tremendous amount of value,” he emphasizes.

The conversation naturally led to the pivotal role of Katalyze AI in this technological transformation. Positioned at the forefront of integrating advanced technology into biomanufacturing, Katalyze AI facilitates smoother data integration and real-time analytics. By harnessing the power of AI, manufacturers can not only enhance operational efficiencies but also adeptly navigate the complexities of contemporary drug development.

Michael asserts that the future of biomanufacturing is contingent upon the industry’s adaptability to these changes. As companies explore AI-driven solutions, they can unlock unprecedented levels of productivity and responsiveness. “In this very, very complex, competitive world, being able to produce even a little bit more from your manufacturing is going to unlock a tremendous amount of value,” he emphasizes.

The conversation naturally led to the pivotal role of Katalyze AI in this technological transformation. Positioned at the forefront of integrating advanced technology into biomanufacturing, Katalyze AI facilitates smoother data integration and real-time analytics. By harnessing the power of AI, manufacturers can not only enhance operational efficiencies but also adeptly navigate the complexities of contemporary drug development.

Michael asserts that the future of biomanufacturing is contingent upon the industry’s adaptability to these changes. As companies explore AI-driven solutions, they can unlock unprecedented levels of productivity and responsiveness. “In this very, very complex, competitive world, being able to produce even a little bit more from your manufacturing is going to unlock a tremendous amount of value,” he emphasizes.

The conversation naturally led to the pivotal role of Katalyze AI in this technological transformation. Positioned at the forefront of integrating advanced technology into biomanufacturing, Katalyze AI facilitates smoother data integration and real-time analytics. By harnessing the power of AI, manufacturers can not only enhance operational efficiencies but also adeptly navigate the complexities of contemporary drug development.

Michael asserts that the future of biomanufacturing is contingent upon the industry’s adaptability to these changes. As companies explore AI-driven solutions, they can unlock unprecedented levels of productivity and responsiveness. “In this very, very complex, competitive world, being able to produce even a little bit more from your manufacturing is going to unlock a tremendous amount of value,” he emphasizes.

The Promise of Artificial Intelligence in Healthcare

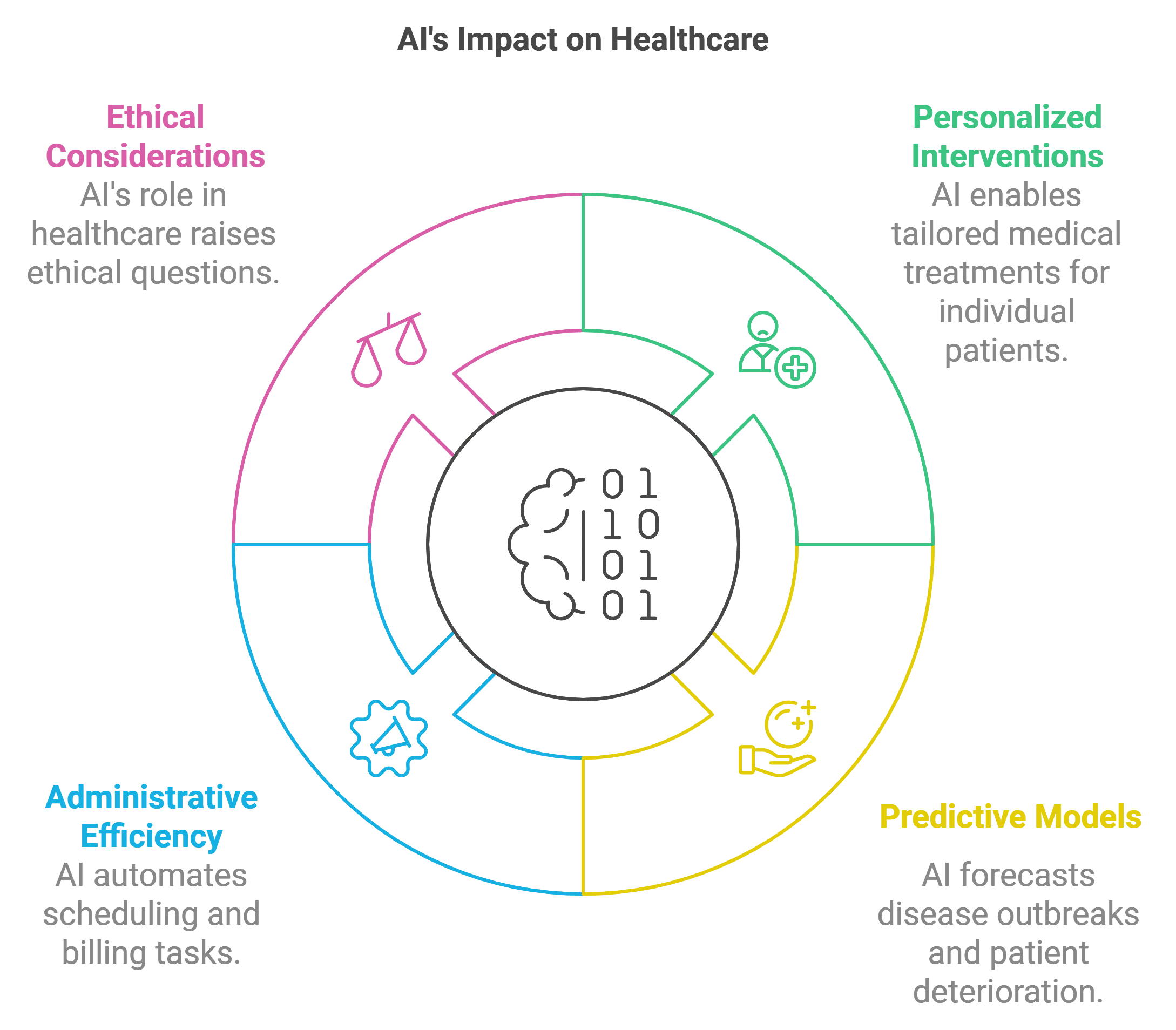

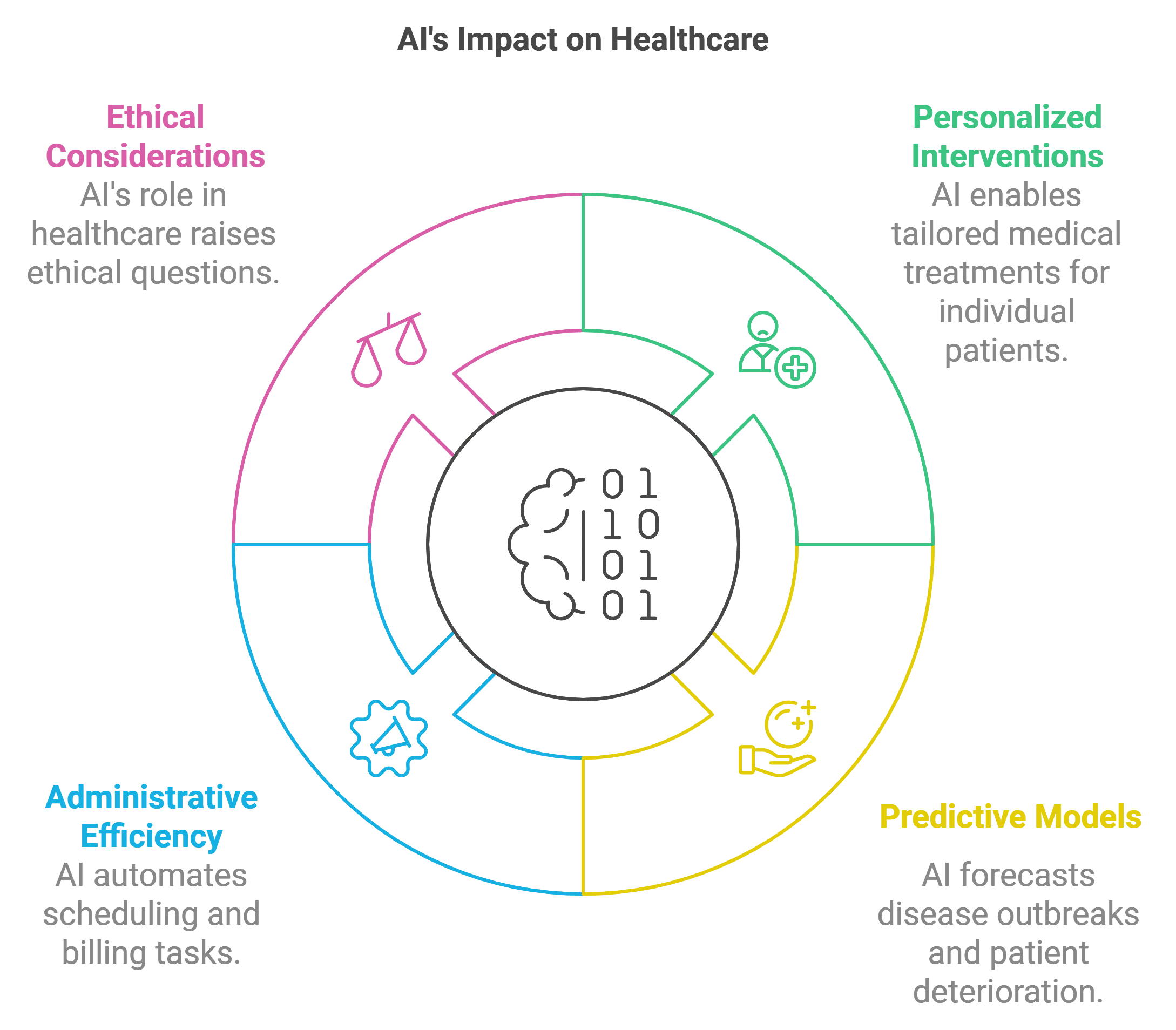

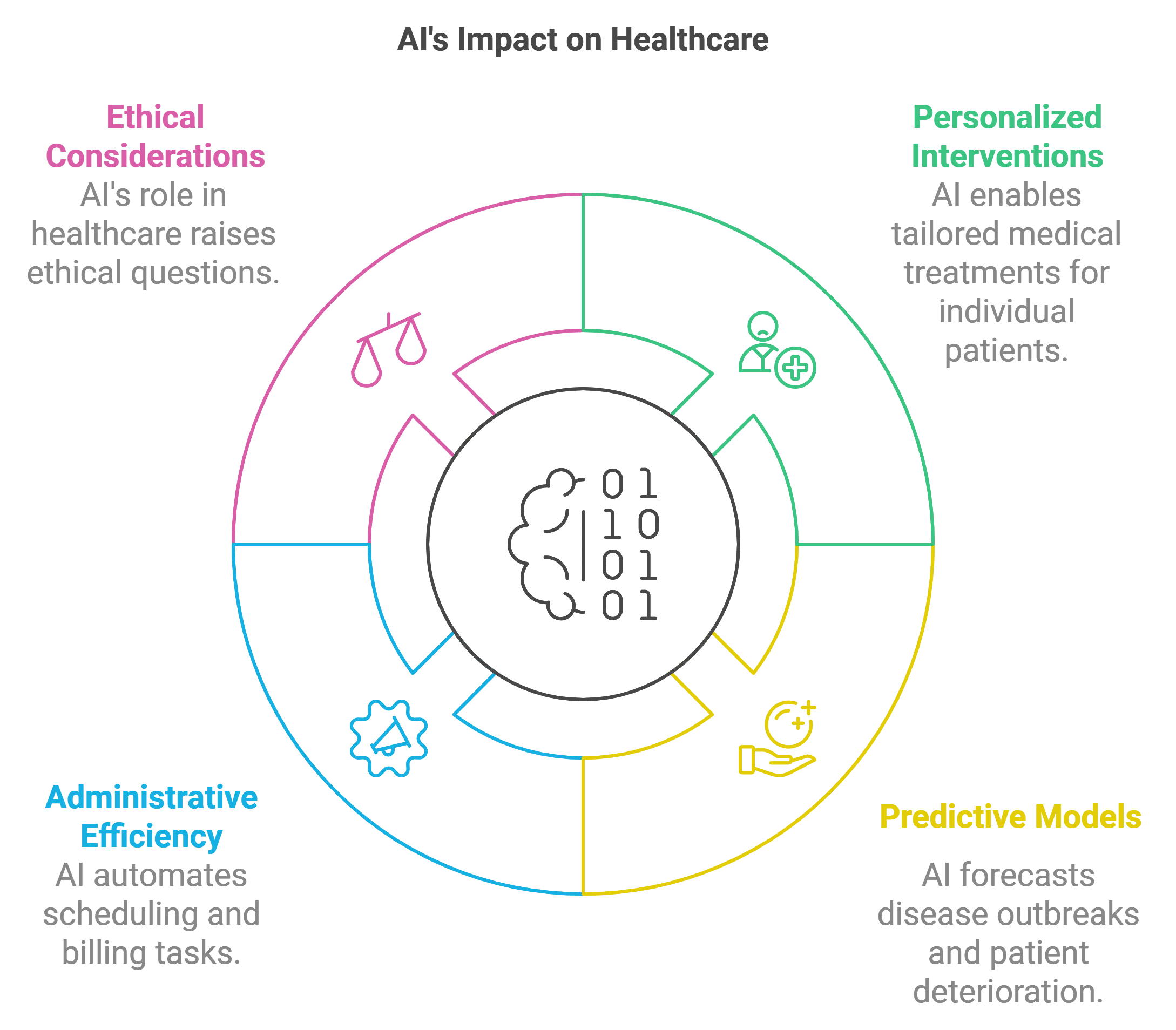

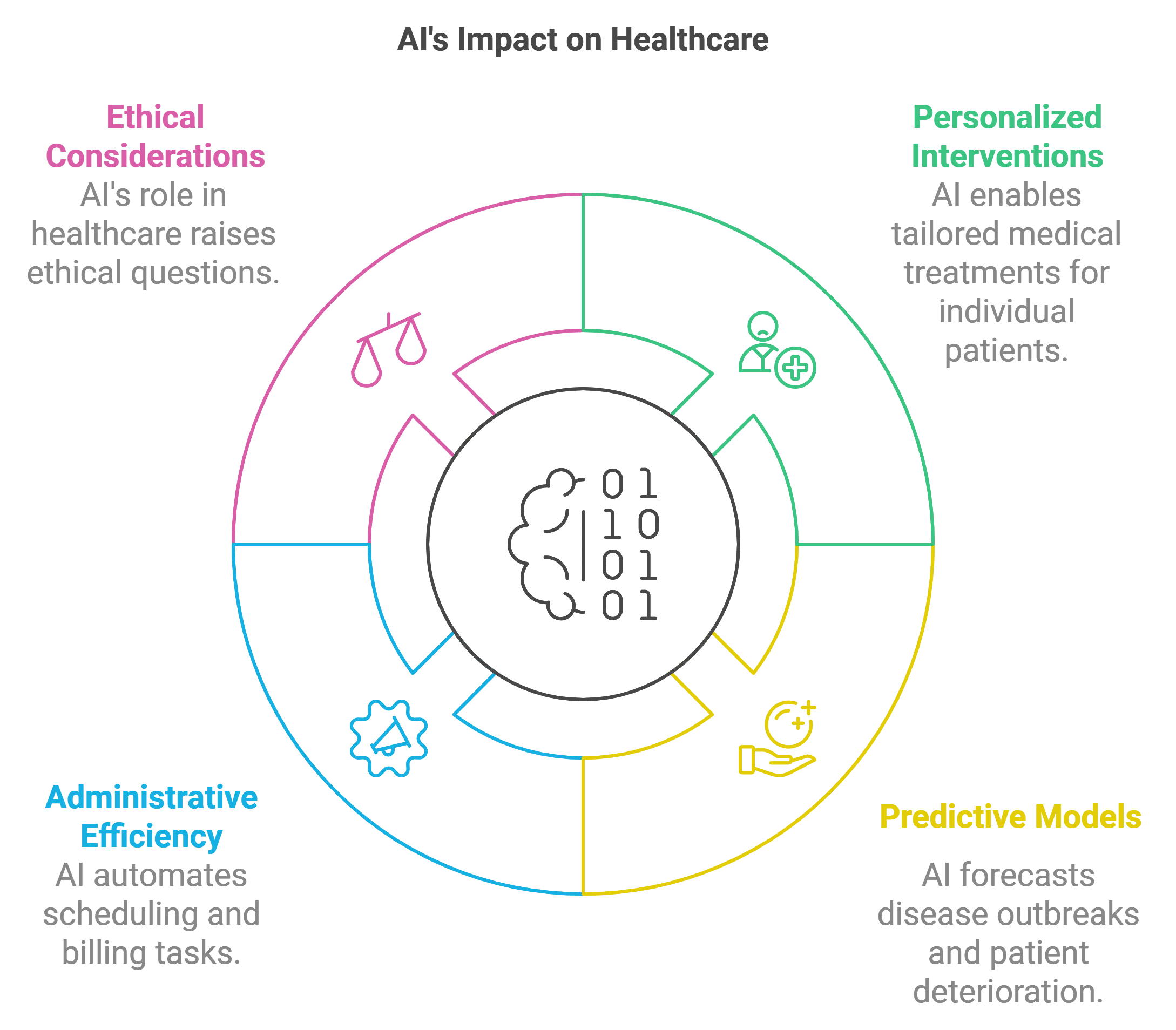

The integration of artificial intelligence (AI) in healthcare is transforming the way medical professionals diagnose, treat, and manage diseases. With its ability to analyze vast datasets, AI is enabling more precise and personalized medical interventions. This shift is not only improving patient outcomes but also enhancing operational efficiencies within healthcare systems.

Recent advancements in AI applications highlight its potential to revolutionize various aspects of healthcare. For instance, a study from Stanford University introduced a graph convolutional network model named Decagon, which predicts drug-drug interactions and their associated side effects. By synthesizing information from diverse data sources, Decagon can identify specific interaction types among nearly 1,000 side effects. This predictive model serves as a decision-support tool for physicians, particularly when prescribing multiple medications, thus significantly enhancing patient safety and clinical outcomes.

As healthcare providers increasingly rely on data-driven insights, the role of AI in predicting disease outbreaks and patient deterioration is also gaining prominence. By utilizing machine learning algorithms, healthcare systems can forecast potential health crises, enabling timely interventions. This proactive approach not only saves lives but also reduces the financial burden on healthcare facilities.

Moreover, AI is enhancing the efficiency of administrative tasks within healthcare organizations. Automating routine processes such as patient scheduling and billing allows healthcare professionals to focus more on patient care rather than administrative burdens. This shift is crucial in a landscape where the demand for healthcare services is steadily increasing.

In conclusion, the ongoing advancements in AI technology present an exciting future for healthcare. With models like Decagon paving the way for safer medication practices and AI systems improving operational efficiency, the potential to elevate patient care to unprecedented levels is within reach. As we continue to explore the capabilities of AI in healthcare, it is essential to address ethical considerations and ensure that these technologies are implemented responsibly.

For more insights on the integration of AI in healthcare, you can read the full article here: BioProcess International.

The integration of artificial intelligence (AI) in healthcare is transforming the way medical professionals diagnose, treat, and manage diseases. With its ability to analyze vast datasets, AI is enabling more precise and personalized medical interventions. This shift is not only improving patient outcomes but also enhancing operational efficiencies within healthcare systems.

Recent advancements in AI applications highlight its potential to revolutionize various aspects of healthcare. For instance, a study from Stanford University introduced a graph convolutional network model named Decagon, which predicts drug-drug interactions and their associated side effects. By synthesizing information from diverse data sources, Decagon can identify specific interaction types among nearly 1,000 side effects. This predictive model serves as a decision-support tool for physicians, particularly when prescribing multiple medications, thus significantly enhancing patient safety and clinical outcomes.

As healthcare providers increasingly rely on data-driven insights, the role of AI in predicting disease outbreaks and patient deterioration is also gaining prominence. By utilizing machine learning algorithms, healthcare systems can forecast potential health crises, enabling timely interventions. This proactive approach not only saves lives but also reduces the financial burden on healthcare facilities.

Moreover, AI is enhancing the efficiency of administrative tasks within healthcare organizations. Automating routine processes such as patient scheduling and billing allows healthcare professionals to focus more on patient care rather than administrative burdens. This shift is crucial in a landscape where the demand for healthcare services is steadily increasing.

In conclusion, the ongoing advancements in AI technology present an exciting future for healthcare. With models like Decagon paving the way for safer medication practices and AI systems improving operational efficiency, the potential to elevate patient care to unprecedented levels is within reach. As we continue to explore the capabilities of AI in healthcare, it is essential to address ethical considerations and ensure that these technologies are implemented responsibly.

For more insights on the integration of AI in healthcare, you can read the full article here: BioProcess International.

The integration of artificial intelligence (AI) in healthcare is transforming the way medical professionals diagnose, treat, and manage diseases. With its ability to analyze vast datasets, AI is enabling more precise and personalized medical interventions. This shift is not only improving patient outcomes but also enhancing operational efficiencies within healthcare systems.

Recent advancements in AI applications highlight its potential to revolutionize various aspects of healthcare. For instance, a study from Stanford University introduced a graph convolutional network model named Decagon, which predicts drug-drug interactions and their associated side effects. By synthesizing information from diverse data sources, Decagon can identify specific interaction types among nearly 1,000 side effects. This predictive model serves as a decision-support tool for physicians, particularly when prescribing multiple medications, thus significantly enhancing patient safety and clinical outcomes.

As healthcare providers increasingly rely on data-driven insights, the role of AI in predicting disease outbreaks and patient deterioration is also gaining prominence. By utilizing machine learning algorithms, healthcare systems can forecast potential health crises, enabling timely interventions. This proactive approach not only saves lives but also reduces the financial burden on healthcare facilities.

Moreover, AI is enhancing the efficiency of administrative tasks within healthcare organizations. Automating routine processes such as patient scheduling and billing allows healthcare professionals to focus more on patient care rather than administrative burdens. This shift is crucial in a landscape where the demand for healthcare services is steadily increasing.

In conclusion, the ongoing advancements in AI technology present an exciting future for healthcare. With models like Decagon paving the way for safer medication practices and AI systems improving operational efficiency, the potential to elevate patient care to unprecedented levels is within reach. As we continue to explore the capabilities of AI in healthcare, it is essential to address ethical considerations and ensure that these technologies are implemented responsibly.

For more insights on the integration of AI in healthcare, you can read the full article here: BioProcess International.

The integration of artificial intelligence (AI) in healthcare is transforming the way medical professionals diagnose, treat, and manage diseases. With its ability to analyze vast datasets, AI is enabling more precise and personalized medical interventions. This shift is not only improving patient outcomes but also enhancing operational efficiencies within healthcare systems.

Recent advancements in AI applications highlight its potential to revolutionize various aspects of healthcare. For instance, a study from Stanford University introduced a graph convolutional network model named Decagon, which predicts drug-drug interactions and their associated side effects. By synthesizing information from diverse data sources, Decagon can identify specific interaction types among nearly 1,000 side effects. This predictive model serves as a decision-support tool for physicians, particularly when prescribing multiple medications, thus significantly enhancing patient safety and clinical outcomes.

As healthcare providers increasingly rely on data-driven insights, the role of AI in predicting disease outbreaks and patient deterioration is also gaining prominence. By utilizing machine learning algorithms, healthcare systems can forecast potential health crises, enabling timely interventions. This proactive approach not only saves lives but also reduces the financial burden on healthcare facilities.

Moreover, AI is enhancing the efficiency of administrative tasks within healthcare organizations. Automating routine processes such as patient scheduling and billing allows healthcare professionals to focus more on patient care rather than administrative burdens. This shift is crucial in a landscape where the demand for healthcare services is steadily increasing.

In conclusion, the ongoing advancements in AI technology present an exciting future for healthcare. With models like Decagon paving the way for safer medication practices and AI systems improving operational efficiency, the potential to elevate patient care to unprecedented levels is within reach. As we continue to explore the capabilities of AI in healthcare, it is essential to address ethical considerations and ensure that these technologies are implemented responsibly.

For more insights on the integration of AI in healthcare, you can read the full article here: BioProcess International.

Michael Burton’s insights illuminate the intricate challenges confronting the biomanufacturing industry today. As organizations navigate this evolving landscape, embracing technological advancements like those offered by Katalyze AI will be vital for achieving sustained success. The future of biomanufacturing is not merely about keeping pace with change; it is about leading through innovation, fostering collaboration, and a commitment to exploring new horizons.

By strategically investing in technology and harnessing the power of AI, the biopharma sector can redefine its operational capabilities, ultimately enhancing the speed and quality of drug development and production. As the industry continues to evolve, staying ahead of these trends will be essential for any organization aspiring to thrive in the biomanufacturing arena.

Michael Burton’s insights illuminate the intricate challenges confronting the biomanufacturing industry today. As organizations navigate this evolving landscape, embracing technological advancements like those offered by Katalyze AI will be vital for achieving sustained success. The future of biomanufacturing is not merely about keeping pace with change; it is about leading through innovation, fostering collaboration, and a commitment to exploring new horizons.

By strategically investing in technology and harnessing the power of AI, the biopharma sector can redefine its operational capabilities, ultimately enhancing the speed and quality of drug development and production. As the industry continues to evolve, staying ahead of these trends will be essential for any organization aspiring to thrive in the biomanufacturing arena.

Michael Burton’s insights illuminate the intricate challenges confronting the biomanufacturing industry today. As organizations navigate this evolving landscape, embracing technological advancements like those offered by Katalyze AI will be vital for achieving sustained success. The future of biomanufacturing is not merely about keeping pace with change; it is about leading through innovation, fostering collaboration, and a commitment to exploring new horizons.

By strategically investing in technology and harnessing the power of AI, the biopharma sector can redefine its operational capabilities, ultimately enhancing the speed and quality of drug development and production. As the industry continues to evolve, staying ahead of these trends will be essential for any organization aspiring to thrive in the biomanufacturing arena.

Michael Burton’s insights illuminate the intricate challenges confronting the biomanufacturing industry today. As organizations navigate this evolving landscape, embracing technological advancements like those offered by Katalyze AI will be vital for achieving sustained success. The future of biomanufacturing is not merely about keeping pace with change; it is about leading through innovation, fostering collaboration, and a commitment to exploring new horizons.

By strategically investing in technology and harnessing the power of AI, the biopharma sector can redefine its operational capabilities, ultimately enhancing the speed and quality of drug development and production. As the industry continues to evolve, staying ahead of these trends will be essential for any organization aspiring to thrive in the biomanufacturing arena.