Mike Tomasco, a distinguished leader in the manufacturing sector, has adeptly navigated the complexities of technological advancement throughout his career. His reflections on pivotal milestones in technology underscore the critical importance of data utilization and the relentless pursuit of operational excellence. Through his experiences, Tomasco illustrates how organizations can not only endure but thrive amidst the relentless tide of change.

Mike Tomasco, a distinguished leader in the manufacturing sector, has adeptly navigated the complexities of technological advancement throughout his career. His reflections on pivotal milestones in technology underscore the critical importance of data utilization and the relentless pursuit of operational excellence. Through his experiences, Tomasco illustrates how organizations can not only endure but thrive amidst the relentless tide of change.

Mike Tomasco, a distinguished leader in the manufacturing sector, has adeptly navigated the complexities of technological advancement throughout his career. His reflections on pivotal milestones in technology underscore the critical importance of data utilization and the relentless pursuit of operational excellence. Through his experiences, Tomasco illustrates how organizations can not only endure but thrive amidst the relentless tide of change.

Mike Tomasco, a distinguished leader in the manufacturing sector, has adeptly navigated the complexities of technological advancement throughout his career. His reflections on pivotal milestones in technology underscore the critical importance of data utilization and the relentless pursuit of operational excellence. Through his experiences, Tomasco illustrates how organizations can not only endure but thrive amidst the relentless tide of change.

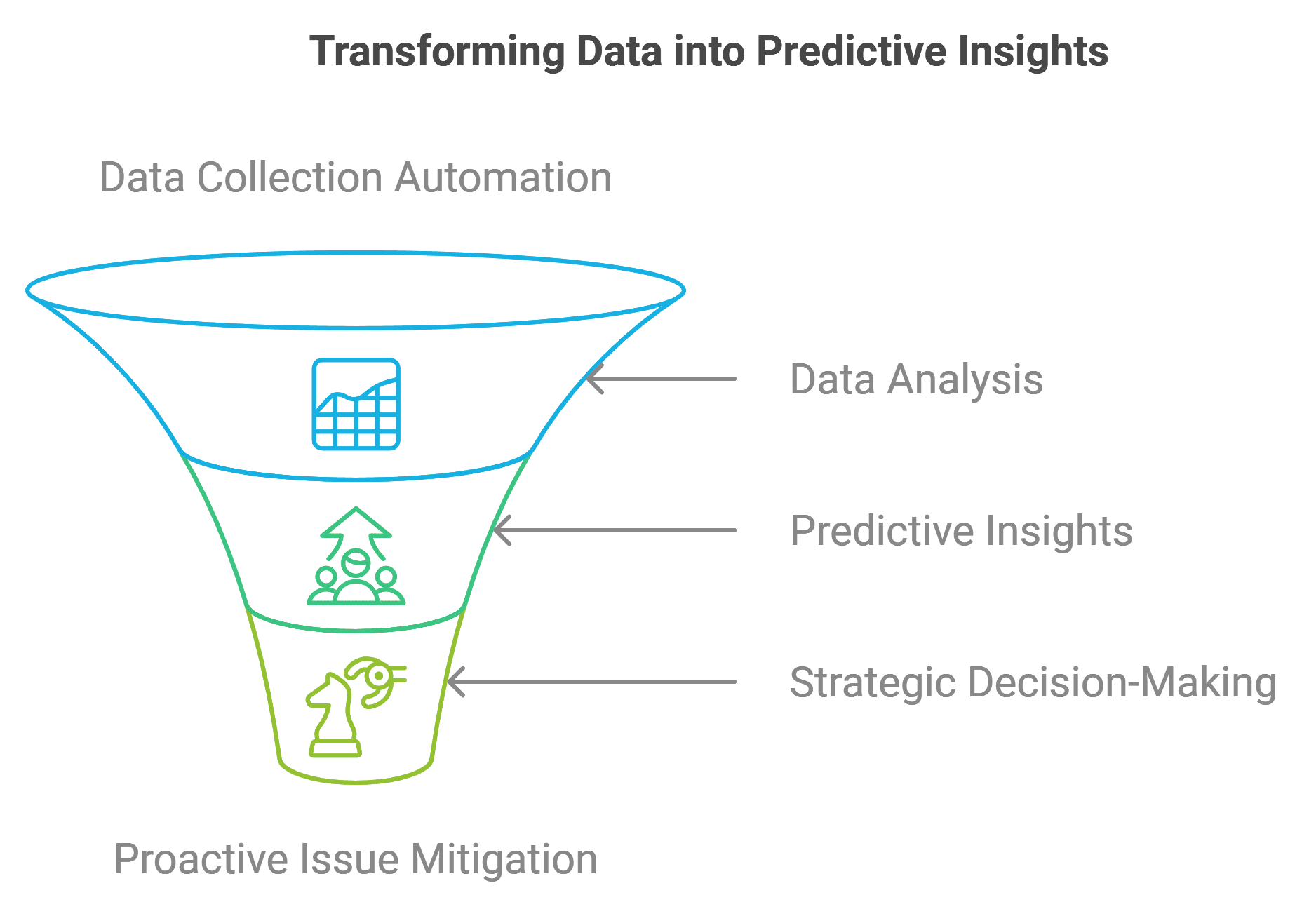

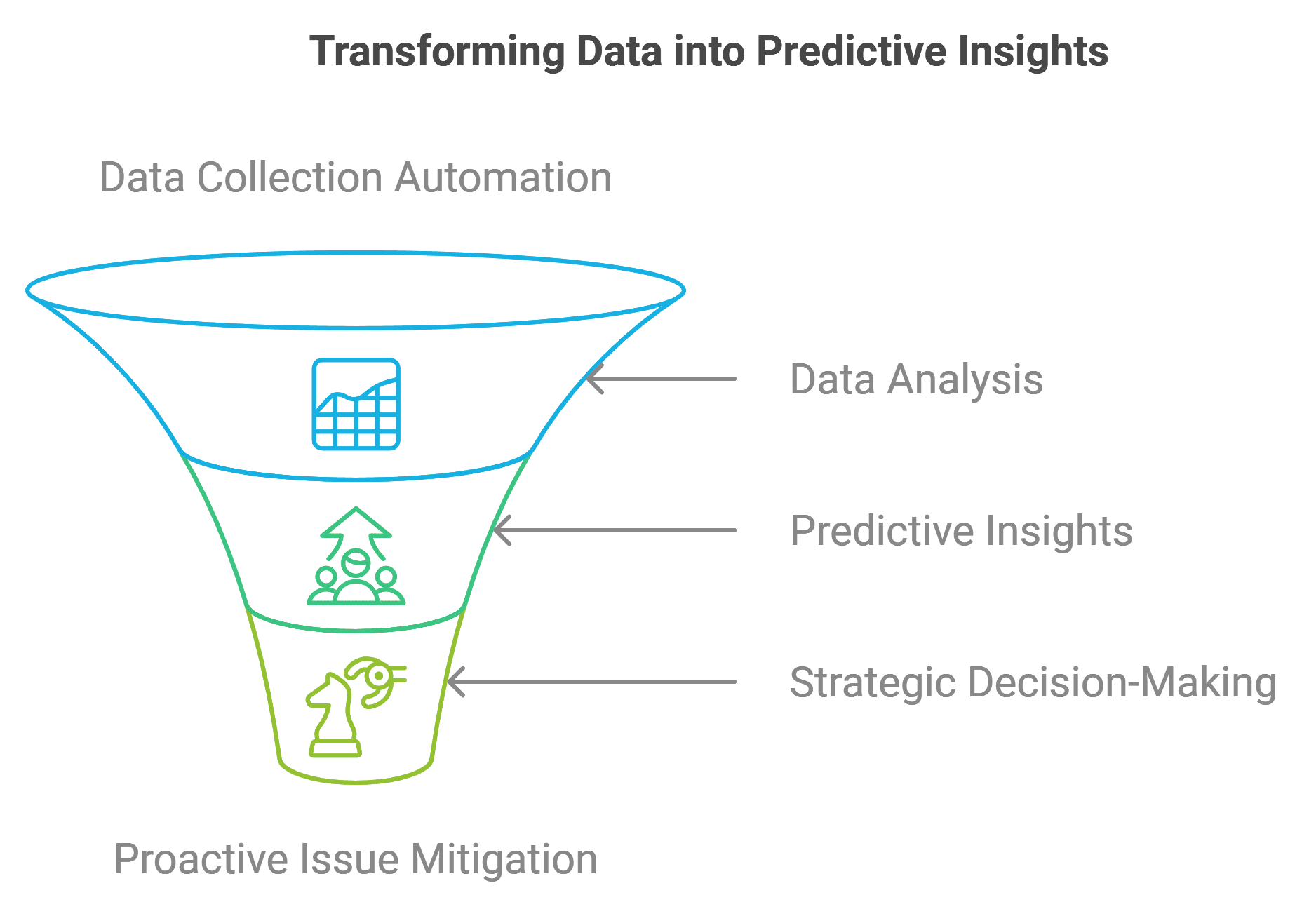

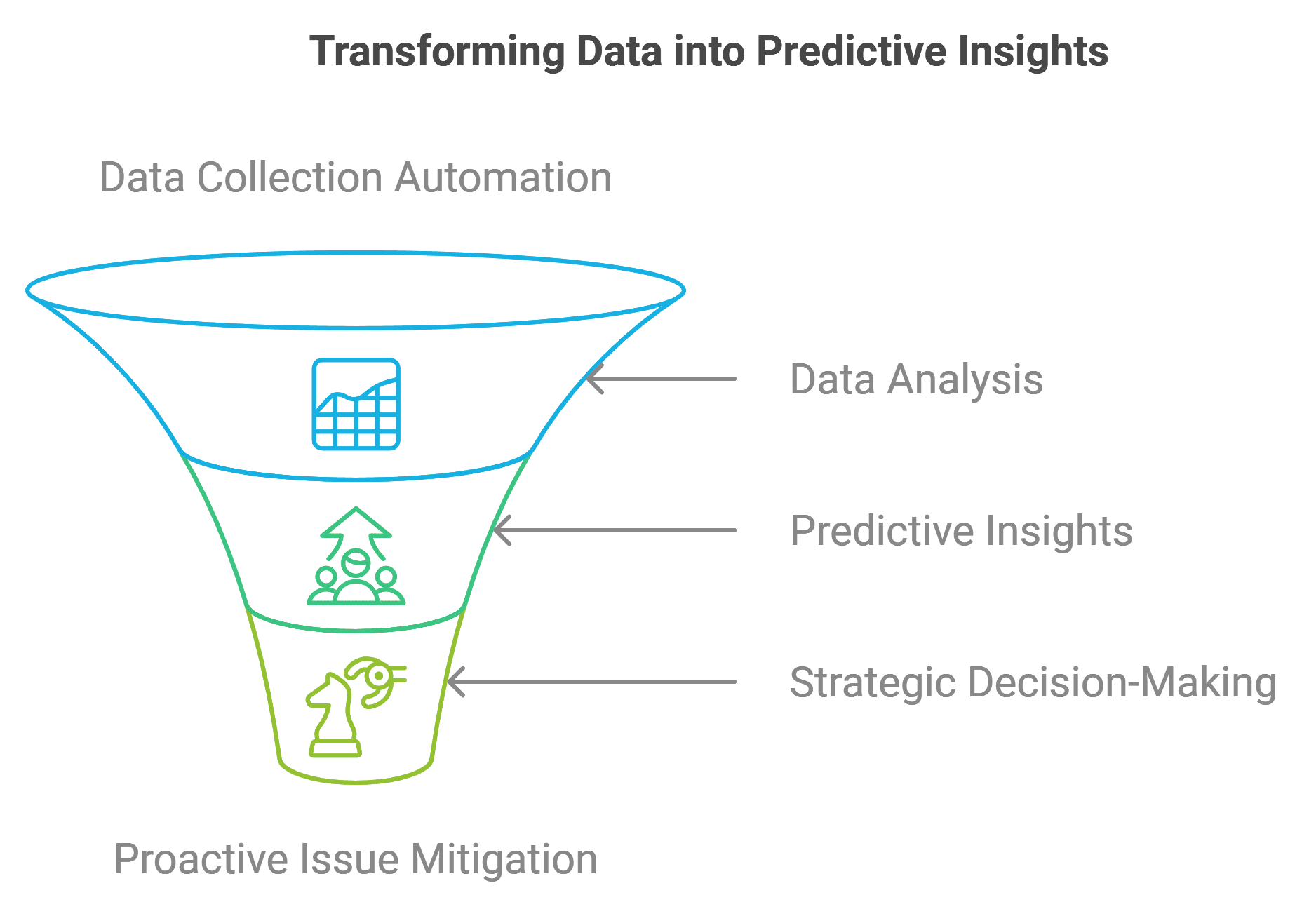

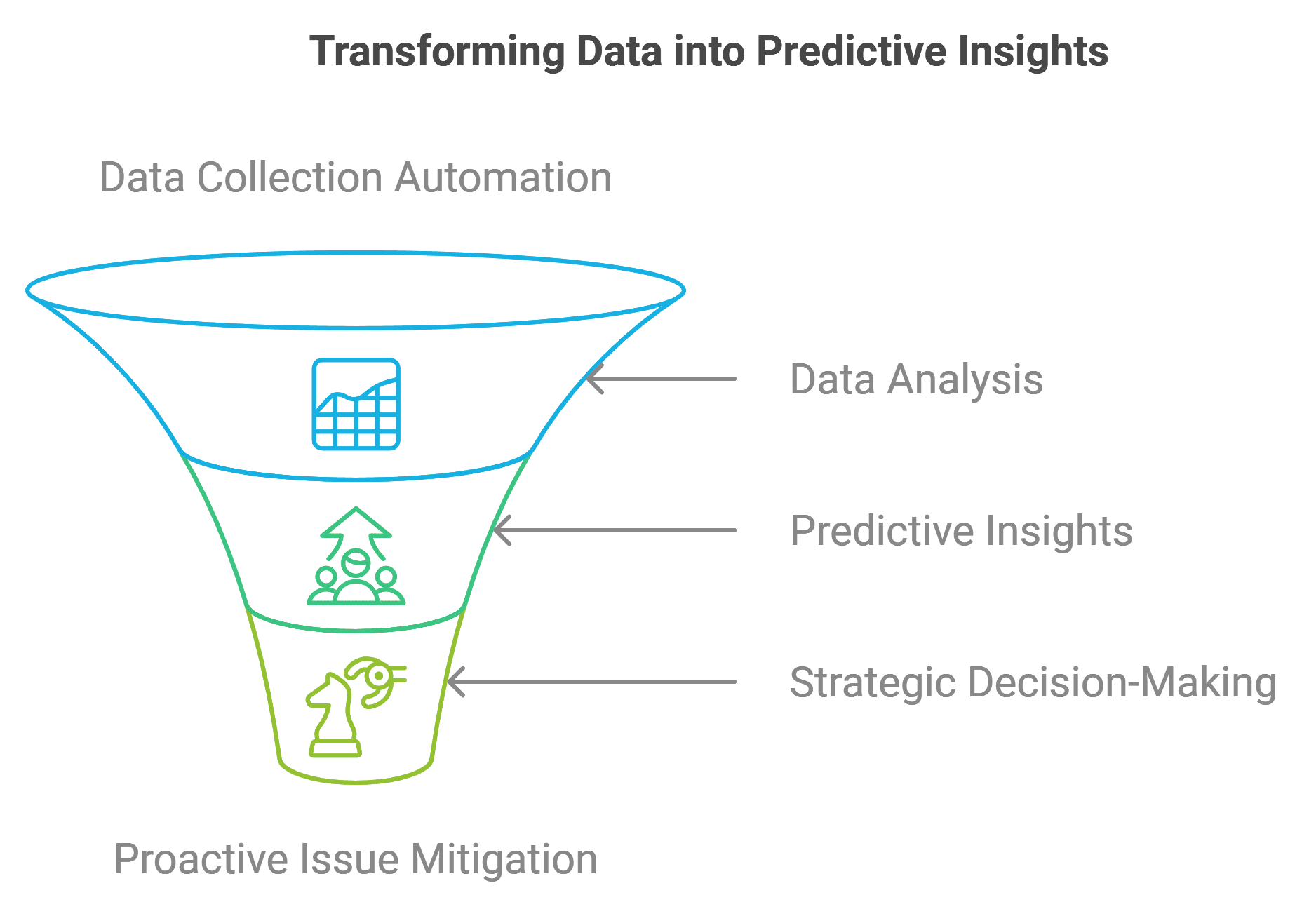

The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur

The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur

The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur

The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur

Memorable Technological Milestones

In recalling his early career, Tomasco reflects on a time when programming in Visual Basic was essential for crafting formulas in Excel. He describes the introduction of the formula button as “magical,” an indication of how innovations can profoundly reshape our workflows. The transformative nature of technology is evident: “The ability to access data and act upon it is far more straightforward than it once was.” This evolution has particularly influenced the manufacturing landscape, transitioning from isolated systems to integrated, enterprise-wide connectivity.

In recalling his early career, Tomasco reflects on a time when programming in Visual Basic was essential for crafting formulas in Excel. He describes the introduction of the formula button as “magical,” an indication of how innovations can profoundly reshape our workflows. The transformative nature of technology is evident: “The ability to access data and act upon it is far more straightforward than it once was.” This evolution has particularly influenced the manufacturing landscape, transitioning from isolated systems to integrated, enterprise-wide connectivity.

In recalling his early career, Tomasco reflects on a time when programming in Visual Basic was essential for crafting formulas in Excel. He describes the introduction of the formula button as “magical,” an indication of how innovations can profoundly reshape our workflows. The transformative nature of technology is evident: “The ability to access data and act upon it is far more straightforward than it once was.” This evolution has particularly influenced the manufacturing landscape, transitioning from isolated systems to integrated, enterprise-wide connectivity.

In recalling his early career, Tomasco reflects on a time when programming in Visual Basic was essential for crafting formulas in Excel. He describes the introduction of the formula button as “magical,” an indication of how innovations can profoundly reshape our workflows. The transformative nature of technology is evident: “The ability to access data and act upon it is far more straightforward than it once was.” This evolution has particularly influenced the manufacturing landscape, transitioning from isolated systems to integrated, enterprise-wide connectivity.

Navigating Cybersecurity Challenges

The advancement of technology brings with it an array of challenges, notably in the realm of cybersecurity. Tomasco identifies cybersecurity threats as a significant concern, advocating for a holistic approach that encompasses both IT and operational technology (OT) layers. He asserts, “When you’re focused on your OT layer, don’t just wall it off. We need a way to bring data out and up into the enterprise.” This integrative approach facilitates improved modeling and real-time decision-making, allowing organizations to adapt to emerging challenges.

In alignment with Tomasco’s insights, a recent study by Deloitte reveals that over 60% of manufacturers are implementing advanced cybersecurity measures tailored specifically for OT. As cyber threats become increasingly sophisticated, organizations recognize the imperative of merging OT and IT security strategies, reinforcing the need for comprehensive measures that protect sensitive data while ensuring operational integrity. This alignment emphasizes the critical importance of a proactive cybersecurity posture in today's interconnected manufacturing environment.

You can access the Deloitte report here.

The advancement of technology brings with it an array of challenges, notably in the realm of cybersecurity. Tomasco identifies cybersecurity threats as a significant concern, advocating for a holistic approach that encompasses both IT and operational technology (OT) layers. He asserts, “When you’re focused on your OT layer, don’t just wall it off. We need a way to bring data out and up into the enterprise.” This integrative approach facilitates improved modeling and real-time decision-making, allowing organizations to adapt to emerging challenges.

In alignment with Tomasco’s insights, a recent study by Deloitte reveals that over 60% of manufacturers are implementing advanced cybersecurity measures tailored specifically for OT. As cyber threats become increasingly sophisticated, organizations recognize the imperative of merging OT and IT security strategies, reinforcing the need for comprehensive measures that protect sensitive data while ensuring operational integrity. This alignment emphasizes the critical importance of a proactive cybersecurity posture in today's interconnected manufacturing environment.

You can access the Deloitte report here.

The advancement of technology brings with it an array of challenges, notably in the realm of cybersecurity. Tomasco identifies cybersecurity threats as a significant concern, advocating for a holistic approach that encompasses both IT and operational technology (OT) layers. He asserts, “When you’re focused on your OT layer, don’t just wall it off. We need a way to bring data out and up into the enterprise.” This integrative approach facilitates improved modeling and real-time decision-making, allowing organizations to adapt to emerging challenges.

In alignment with Tomasco’s insights, a recent study by Deloitte reveals that over 60% of manufacturers are implementing advanced cybersecurity measures tailored specifically for OT. As cyber threats become increasingly sophisticated, organizations recognize the imperative of merging OT and IT security strategies, reinforcing the need for comprehensive measures that protect sensitive data while ensuring operational integrity. This alignment emphasizes the critical importance of a proactive cybersecurity posture in today's interconnected manufacturing environment.

You can access the Deloitte report here.

The advancement of technology brings with it an array of challenges, notably in the realm of cybersecurity. Tomasco identifies cybersecurity threats as a significant concern, advocating for a holistic approach that encompasses both IT and operational technology (OT) layers. He asserts, “When you’re focused on your OT layer, don’t just wall it off. We need a way to bring data out and up into the enterprise.” This integrative approach facilitates improved modeling and real-time decision-making, allowing organizations to adapt to emerging challenges.

In alignment with Tomasco’s insights, a recent study by Deloitte reveals that over 60% of manufacturers are implementing advanced cybersecurity measures tailored specifically for OT. As cyber threats become increasingly sophisticated, organizations recognize the imperative of merging OT and IT security strategies, reinforcing the need for comprehensive measures that protect sensitive data while ensuring operational integrity. This alignment emphasizes the critical importance of a proactive cybersecurity posture in today's interconnected manufacturing environment.

You can access the Deloitte report here.

Learning from Failures in Data Management

Tomasco’s journey offers a crucial lesson in data management: the dangers of moving data to the cloud without a coherent strategy. He recounts an initial, unsuccessful attempt to consolidate all company data, which led to disarray. “The second time we tried it, we adopted a use-case-driven approach,” he explains. By selectively integrating data sets from the ERP, quality assurance, and lab systems, the team was able to develop analytical applications that yielded significant efficiencies and insights. This experience highlights the necessity of strategic planning in data management initiatives.

Tomasco’s journey offers a crucial lesson in data management: the dangers of moving data to the cloud without a coherent strategy. He recounts an initial, unsuccessful attempt to consolidate all company data, which led to disarray. “The second time we tried it, we adopted a use-case-driven approach,” he explains. By selectively integrating data sets from the ERP, quality assurance, and lab systems, the team was able to develop analytical applications that yielded significant efficiencies and insights. This experience highlights the necessity of strategic planning in data management initiatives.

Tomasco’s journey offers a crucial lesson in data management: the dangers of moving data to the cloud without a coherent strategy. He recounts an initial, unsuccessful attempt to consolidate all company data, which led to disarray. “The second time we tried it, we adopted a use-case-driven approach,” he explains. By selectively integrating data sets from the ERP, quality assurance, and lab systems, the team was able to develop analytical applications that yielded significant efficiencies and insights. This experience highlights the necessity of strategic planning in data management initiatives.

Tomasco’s journey offers a crucial lesson in data management: the dangers of moving data to the cloud without a coherent strategy. He recounts an initial, unsuccessful attempt to consolidate all company data, which led to disarray. “The second time we tried it, we adopted a use-case-driven approach,” he explains. By selectively integrating data sets from the ERP, quality assurance, and lab systems, the team was able to develop analytical applications that yielded significant efficiencies and insights. This experience highlights the necessity of strategic planning in data management initiatives.

The ability to access data and act upon it is far more straightforward than it once was.

The ability to access data and act upon it is far more straightforward than it once was.

The ability to access data and act upon it is far more straightforward than it once was.

The ability to access data and act upon it is far more straightforward than it once was.

Enhancing Cross-Functional Collaboration

A hallmark of Tomasco’s leadership is his commitment to fostering cross-functional collaboration within the manufacturing plant. He identified a pervasive issue: “In a weekly or daily huddle, everyone arrives with their own set of information.” This siloed mentality often resulted in confusion and inefficiency. By standardizing data and creating shared experiences, teams could more accurately track processes, identify bottlenecks, and take informed actions to enhance performance. Implementing a lean production system, inspired by Toyota’s methodologies, helped instill a culture of continuous improvement.

A hallmark of Tomasco’s leadership is his commitment to fostering cross-functional collaboration within the manufacturing plant. He identified a pervasive issue: “In a weekly or daily huddle, everyone arrives with their own set of information.” This siloed mentality often resulted in confusion and inefficiency. By standardizing data and creating shared experiences, teams could more accurately track processes, identify bottlenecks, and take informed actions to enhance performance. Implementing a lean production system, inspired by Toyota’s methodologies, helped instill a culture of continuous improvement.

A hallmark of Tomasco’s leadership is his commitment to fostering cross-functional collaboration within the manufacturing plant. He identified a pervasive issue: “In a weekly or daily huddle, everyone arrives with their own set of information.” This siloed mentality often resulted in confusion and inefficiency. By standardizing data and creating shared experiences, teams could more accurately track processes, identify bottlenecks, and take informed actions to enhance performance. Implementing a lean production system, inspired by Toyota’s methodologies, helped instill a culture of continuous improvement.

A hallmark of Tomasco’s leadership is his commitment to fostering cross-functional collaboration within the manufacturing plant. He identified a pervasive issue: “In a weekly or daily huddle, everyone arrives with their own set of information.” This siloed mentality often resulted in confusion and inefficiency. By standardizing data and creating shared experiences, teams could more accurately track processes, identify bottlenecks, and take informed actions to enhance performance. Implementing a lean production system, inspired by Toyota’s methodologies, helped instill a culture of continuous improvement.

Digital Transformation and Lean Operations

The establishment of the Digital Operations Center represents a paradigm shift in lean manufacturing practices. This initiative aimed to digitize paper-driven processes, enabling real-time collaboration and communication. During a plant tour, Tomasco noted the limitations of physical metrics displayed on magnet boards, which often obfuscated communication. “We learned early on that digitization could simplify the experience,” he noted. This transformation allowed employees to concentrate on their core responsibilities rather than administrative tasks, leading to significant productivity gains.

The establishment of the Digital Operations Center represents a paradigm shift in lean manufacturing practices. This initiative aimed to digitize paper-driven processes, enabling real-time collaboration and communication. During a plant tour, Tomasco noted the limitations of physical metrics displayed on magnet boards, which often obfuscated communication. “We learned early on that digitization could simplify the experience,” he noted. This transformation allowed employees to concentrate on their core responsibilities rather than administrative tasks, leading to significant productivity gains.

The establishment of the Digital Operations Center represents a paradigm shift in lean manufacturing practices. This initiative aimed to digitize paper-driven processes, enabling real-time collaboration and communication. During a plant tour, Tomasco noted the limitations of physical metrics displayed on magnet boards, which often obfuscated communication. “We learned early on that digitization could simplify the experience,” he noted. This transformation allowed employees to concentrate on their core responsibilities rather than administrative tasks, leading to significant productivity gains.

The establishment of the Digital Operations Center represents a paradigm shift in lean manufacturing practices. This initiative aimed to digitize paper-driven processes, enabling real-time collaboration and communication. During a plant tour, Tomasco noted the limitations of physical metrics displayed on magnet boards, which often obfuscated communication. “We learned early on that digitization could simplify the experience,” he noted. This transformation allowed employees to concentrate on their core responsibilities rather than administrative tasks, leading to significant productivity gains.

The Future of Predictive Analytics

As digital transformation progressed, Tomasco observed a shift from merely collecting data to harnessing it for predictive analytics. By automating data collection and leveraging advanced algorithms, teams can identify potential issues proactively. He emphasizes, “The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur.” The integration of generative AI further enhances this capability, acting as a co-pilot for strategic decision-making.

As digital transformation progressed, Tomasco observed a shift from merely collecting data to harnessing it for predictive analytics. By automating data collection and leveraging advanced algorithms, teams can identify potential issues proactively. He emphasizes, “The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur.” The integration of generative AI further enhances this capability, acting as a co-pilot for strategic decision-making.

As digital transformation progressed, Tomasco observed a shift from merely collecting data to harnessing it for predictive analytics. By automating data collection and leveraging advanced algorithms, teams can identify potential issues proactively. He emphasizes, “The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur.” The integration of generative AI further enhances this capability, acting as a co-pilot for strategic decision-making.

As digital transformation progressed, Tomasco observed a shift from merely collecting data to harnessing it for predictive analytics. By automating data collection and leveraging advanced algorithms, teams can identify potential issues proactively. He emphasizes, “The ultimate goal isn’t merely to digitize processes but to predict outcomes and mitigate issues before they occur.” The integration of generative AI further enhances this capability, acting as a co-pilot for strategic decision-making.

The Importance of User Experience in Industrial Software

Tomasco emphasizes the necessity for user-friendly interfaces in industrial software. Drawing parallels to the intuitive design of consumer technology, he questions why industrial applications remain overly complex. “Why are we not developing quality assurance capabilities that are as accessible as our personal devices?” he asks, underscoring the demand for openness in software platforms. Given the diverse nature of manufacturing environments, where equipment varies across facilities, the ability to integrate data through APIs is essential for achieving operational success.

Tomasco emphasizes the necessity for user-friendly interfaces in industrial software. Drawing parallels to the intuitive design of consumer technology, he questions why industrial applications remain overly complex. “Why are we not developing quality assurance capabilities that are as accessible as our personal devices?” he asks, underscoring the demand for openness in software platforms. Given the diverse nature of manufacturing environments, where equipment varies across facilities, the ability to integrate data through APIs is essential for achieving operational success.

Tomasco emphasizes the necessity for user-friendly interfaces in industrial software. Drawing parallels to the intuitive design of consumer technology, he questions why industrial applications remain overly complex. “Why are we not developing quality assurance capabilities that are as accessible as our personal devices?” he asks, underscoring the demand for openness in software platforms. Given the diverse nature of manufacturing environments, where equipment varies across facilities, the ability to integrate data through APIs is essential for achieving operational success.

Tomasco emphasizes the necessity for user-friendly interfaces in industrial software. Drawing parallels to the intuitive design of consumer technology, he questions why industrial applications remain overly complex. “Why are we not developing quality assurance capabilities that are as accessible as our personal devices?” he asks, underscoring the demand for openness in software platforms. Given the diverse nature of manufacturing environments, where equipment varies across facilities, the ability to integrate data through APIs is essential for achieving operational success.

Mike Tomasco’s insights into the intersection of technology and manufacturing yield vital lessons for leaders navigating this dynamic landscape. By learning from past missteps, embracing collaborative strategies, and prioritizing user experience, organizations can adeptly leverage technology to foster operational excellence. The journey of digital transformation transcends the mere adoption of new tools; it is fundamentally about refining processes and empowering individuals to focus on impactful work.

As organizations continue to evolve in their digital endeavors, solutions like KatalyzeAI are poised to offer AI-driven insights and tools that enhance decision-making, streamline operations, and bolster cybersecurity measures. Embracing such innovative solutions will be crucial for manufacturing leaders seeking to maintain a competitive edge in an increasingly complex landscape.

Mike Tomasco’s insights into the intersection of technology and manufacturing yield vital lessons for leaders navigating this dynamic landscape. By learning from past missteps, embracing collaborative strategies, and prioritizing user experience, organizations can adeptly leverage technology to foster operational excellence. The journey of digital transformation transcends the mere adoption of new tools; it is fundamentally about refining processes and empowering individuals to focus on impactful work.

As organizations continue to evolve in their digital endeavors, solutions like KatalyzeAI are poised to offer AI-driven insights and tools that enhance decision-making, streamline operations, and bolster cybersecurity measures. Embracing such innovative solutions will be crucial for manufacturing leaders seeking to maintain a competitive edge in an increasingly complex landscape.

Mike Tomasco’s insights into the intersection of technology and manufacturing yield vital lessons for leaders navigating this dynamic landscape. By learning from past missteps, embracing collaborative strategies, and prioritizing user experience, organizations can adeptly leverage technology to foster operational excellence. The journey of digital transformation transcends the mere adoption of new tools; it is fundamentally about refining processes and empowering individuals to focus on impactful work.

As organizations continue to evolve in their digital endeavors, solutions like KatalyzeAI are poised to offer AI-driven insights and tools that enhance decision-making, streamline operations, and bolster cybersecurity measures. Embracing such innovative solutions will be crucial for manufacturing leaders seeking to maintain a competitive edge in an increasingly complex landscape.

Mike Tomasco’s insights into the intersection of technology and manufacturing yield vital lessons for leaders navigating this dynamic landscape. By learning from past missteps, embracing collaborative strategies, and prioritizing user experience, organizations can adeptly leverage technology to foster operational excellence. The journey of digital transformation transcends the mere adoption of new tools; it is fundamentally about refining processes and empowering individuals to focus on impactful work.

As organizations continue to evolve in their digital endeavors, solutions like KatalyzeAI are poised to offer AI-driven insights and tools that enhance decision-making, streamline operations, and bolster cybersecurity measures. Embracing such innovative solutions will be crucial for manufacturing leaders seeking to maintain a competitive edge in an increasingly complex landscape.